Product inspections

Quality inspections are crucial for any company working with a Chinese supplier. The main goal is to ensure that products are manufactured according to the Client's requirements and are free from any defects before they are accepted from the factory.

Our independent inspectors thoroughly verify whether your goods meet specified quality, functionality, and performance standards. This helps you avoid introducing products to the market that could harm your customers and your brand.

Quality control at every stage of production

Initial Production Check (IPC)

A quality control process conducted at the beginning of production to inspect the first batch of products and ensure they meet specified specifications and Client requirements.

- Ensures that production starts correctly and meets quality standards from the very beginning.

- Allows early identification of production issues, enabling timely corrective actions.

- Prevents the large-scale production of defective products, reducing costs and the need for rework.

During Production Check (DUPRO)

A type of inspection carried out during the production process to monitor product quality as production progresses.

- Monitors product quality throughout production, minimizing the risk of defects.

- Enables timely intervention to resolve issues, preventing delays and disruptions.

- Provides insights into production efficiency, allowing continuous improvement.

Pre-Shipment Inspection (PSI)

The most popular type of quality control conducted after production is completed and just before goods are shipped, ensuring they meet specified quality standards and Client requirements.

- Verifies that finished products meet the required quality standards and Client expectations before shipment.

- Reduces the risk of receiving defective products and ensures that only acceptable goods are shipped.

- Minimizes the likelihood of complaints and returns.

Container Loading Check (CLC)

A quality control process conducted to verify that goods are correctly, safely, and according to specified requirements loaded into transport containers before shipment.

- Ensures that goods are loaded correctly, safely, and in compliance with requirements.

- Helps prevent damage or loss of products during transportation by ensuring proper conditions, loading, and securing.

- Minimizes the risk of shipping incorrect items or errors such as wrong quantities or mixed shipments.

Product categories we check during inspections

Softlines

Hardlines

Electrical and electronic

Toys

How is a product inspection done?

For all product inspections, we use the international statistical sampling procedure ANSI / ASQ Z1.4 (ISO 2859-1). This ensures that inspected products are selected by our inspector and not the supplier. To determine the sample size and acceptance threshold, we use the international standard Acceptable Quality Level (AQL).

During the inspection, the InspectoHub inspector checks products according to a detailed checklist.

The checklist is tailored to the specific product and the individual needs of the Client. The inspection typically verifies areas such as:

- Specification

- Dimensions

- Functionality

- Workmanship & Visual

- Packaging, Labels & Markings

- Special Tests

Who are our inspectors?

With years of experience in quality control in China, we have built a trusted network of local inspectors. We only work with inspectors we personally recruit and know their professional background. Depending on the inspected goods, we assign inspectors with expertise in the respective product category. Our goal is to ensure the highest quality of our services, with credibility and reliability as our top priorities.

Why conduct product inspections?

- Reputation: Deliver top-quality products and strengthen your brand image.

- Cost Savings: Detect defects early to avoid complaints and costly returns.

- Consistency: Verify that products meet your specifications, ensuring uniform quality.

- Trust: Build customer loyalty and trust through high-quality products.

- Compliance: Ensure product compliance with market regulations, minimizing legal risks.

- Continuity: Avoid supply chain disruptions caused by defective products.

- Insight: Assess supplier capabilities to make informed decisions.

- Transparency: Promote ethical practices and accountability.

- Safety: Protect business interests by delivering the highest quality products.

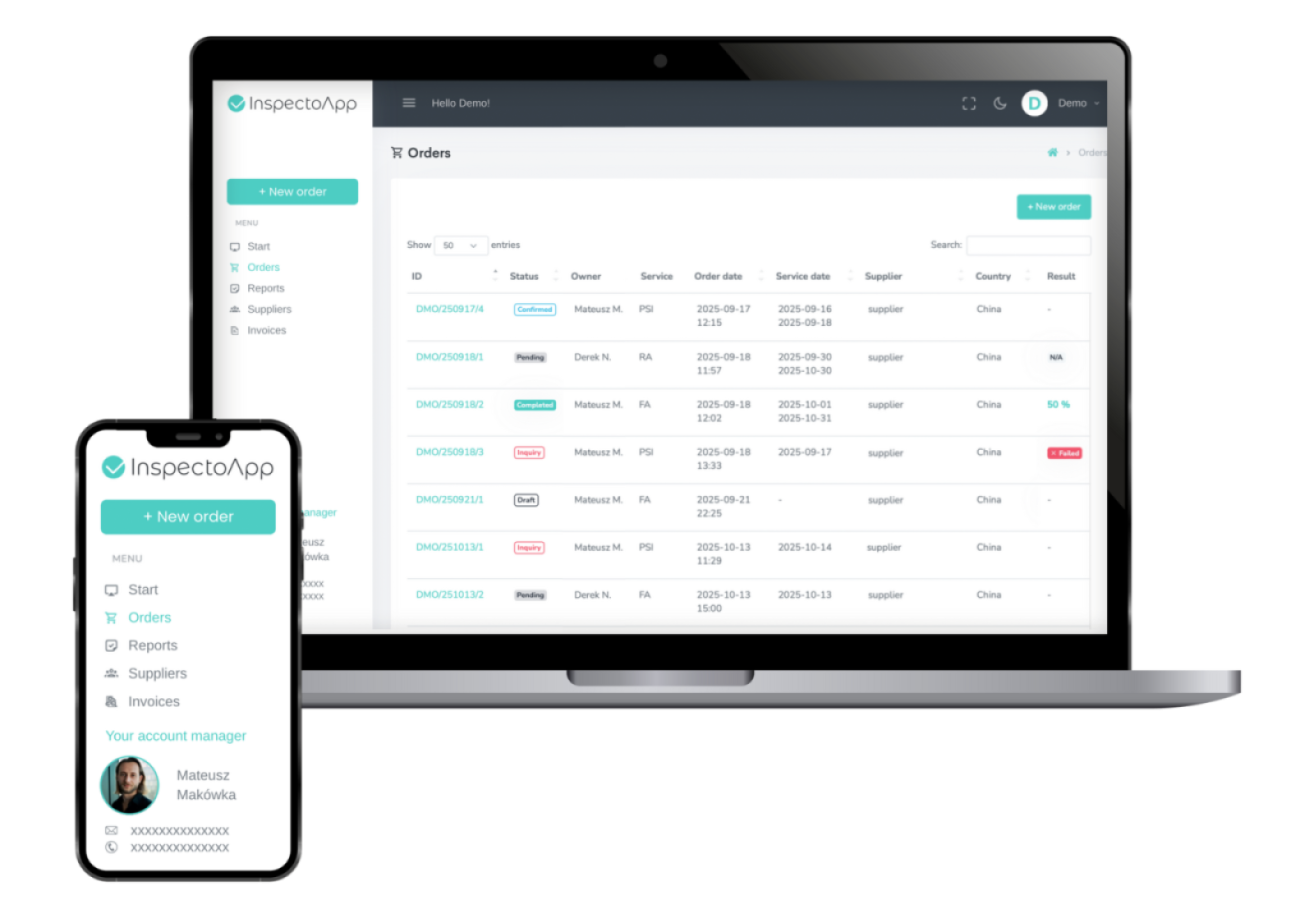

©InspectoApp – Your platform for managing inspections and audits

Order product inspections and supplier audits online and track their status in real time. With ©InspectoApp, you can access all your inspection and audit orders in one place. Just a few clicks are enough to schedule a new inspection and receive your report.

- Place orders quickly and easily

- Track the status of your inspections

- Receive detailed reports

- Access product and supplier analytics

How do Clients get results?

After the product inspection is completed, the inspector prepares a comprehensive report, which is then delivered to the Client. The report includes detailed test results, photos of defective items, and their descriptions. Each report also comes with a file containing all photos taken during the inspection.