Supplier audits

A supplier audit is a critical process designed to protect Clients from dishonest partners. Factory audits are typically conducted before entering into a partnership with a supplier to verify their reliability, available resources, and several other factors that significantly impact the quality of the collaboration.

With our experienced auditors, you can thoroughly evaluate your supplier, which greatly enhances the security of the entire production process.

Supplier audit types based on your needs

Factory Audit

This is an in-depth audit of the factory where we check:

- Legal Aspects: We review the supplier's founding documents, business licenses, certifications, insurance policies, and contact details.

- Financial Health: We assess the financial condition by analyzing turnover, profits, debt ratios from the past three years, and bank information. This data is crucial for evaluating the supplier’s financial stability.

- Production Capacity: We evaluate the factory’s production capacity to determine if the supplier can meet order deadlines and quantities. This includes reviewing the availability of machinery, production technologies, and overall process efficiency.

- Quality Management Systems: We check the supplier’s quality management system to ensure their processes comply with established quality standards. We assess how the supplier monitors and improves product quality and what control measures are in place at different production stages.

- Human Resources and Work Environment: We review the supplier’s human resources management by checking the employee list, work schedules, and compensation systems. We also evaluate the work environment, ensuring that emergency exits, lighting, fire safety equipment, walkways, personal protective gear, first aid kits, access to clean drinking water, and chemicals are properly managed. A safe work environment reduces the risk of accidents and ensures optimal working conditions for both employees and the environment.

- Environmental Protection: We review the supplier’s environmental protection practices by analyzing documents and reports on energy and water conservation, as well as efforts to reduce noise, wastewater, air pollution emissions, and hazardous waste within the factory.

Remote Audit

A remote audit is conducted where the auditor contacts the supplier to verify the following documents:

- Founding documents

- Business licenses

- Bank account details

- Supplier insurance

Who are our auditors?

Our audits are carried out by auditors we personally know and recruit. To ensure the reliability and integrity of our services, we make sure our auditors have the necessary qualifications, experience, and industry knowledge. We regularly conduct training and updates to keep them aligned with the latest standards and regulations. This ensures that our Clients can trust our audits are carried out professionally, impartially, and in line with the highest quality standards.

Why are supplier audits important?

Evaluating a supplier’s factory quality is a crucial process to ensure timely and defect-free product delivery to Clients. Missed deadlines or defective products can harm your company’s reputation. Conducting supplier quality assessments is an essential tool for identifying, addressing, and preventing potential quality issues in products, processes, or the supplier’s management system before they escalate.

Lack of proper management can expose buyers to various risks, including financial losses, damage to brand reputation, and legal disputes due to poor supplier performance related to social compliance, environmental standards, technical requirements, and safety.

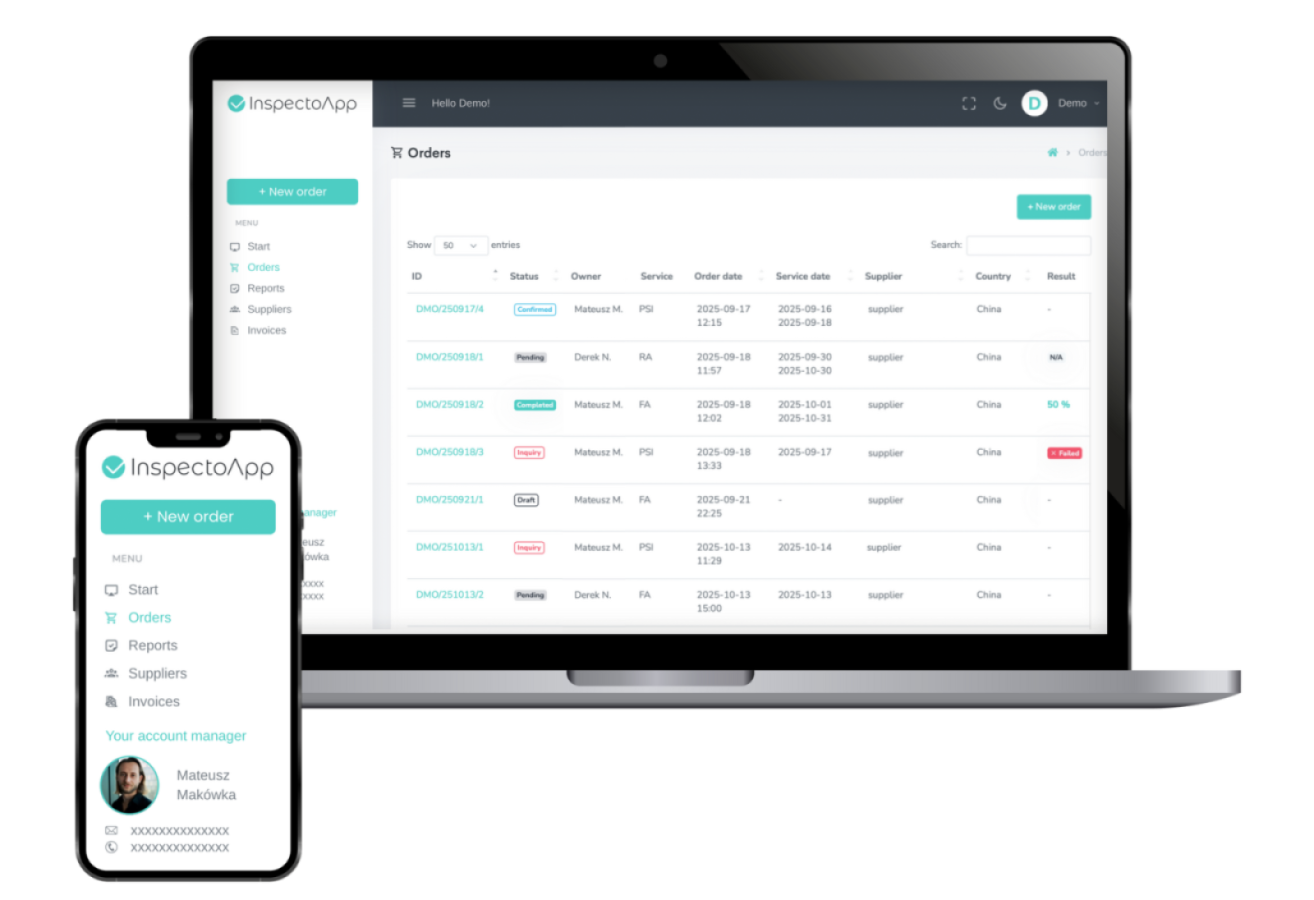

©InspectoApp – Your platform for managing inspections and audits

Order product inspections and supplier audits online and track their status in real time. With ©InspectoApp, you can access all your inspection and audit orders in one place. Just a few clicks are enough to schedule a new audit and receive your report.

- Place orders quickly and easily

- Track the status of your audits

- Receive detailed reports

- Access product and supplier analytics

How do Clients get results?

Once the audit is completed, the auditor prepares a detailed report, which includes a file with all the photos taken during the audit. Upon request, we can also provide video recordings from the factory visit.